In today’s fast-paced digital landscape, having the right tools at your fingertips can make all the difference between a smooth workflow and a frustrating project stall. Enter Qidi Software for XPro—a powerhouse solution to elevate your 3D printing experience.

Whether you’re a seasoned professional or an enthusiastic hobbyist, understanding how to harness the full potential of this innovative software is crucial. But what happens when complications arise? Knowing how to troubleshoot these issues effectively can save time and valuable resources.

In this article, we’ll explore the intricacies of Qidi Software for XPro, its advanced features, and standard troubleshooting techniques.

Contents

- 1 Introduction to Qidi Software for XPro

- 2 Common Issues with Qidi Software for XPro and How to Troubleshoot Them

- 3 Advanced Features of Qidi Software for XPro

- 4 Best Practices for Using Qidi Software for XPro

- 5 Frequently Asked Questions (FAQs)

- 6 Conclusion

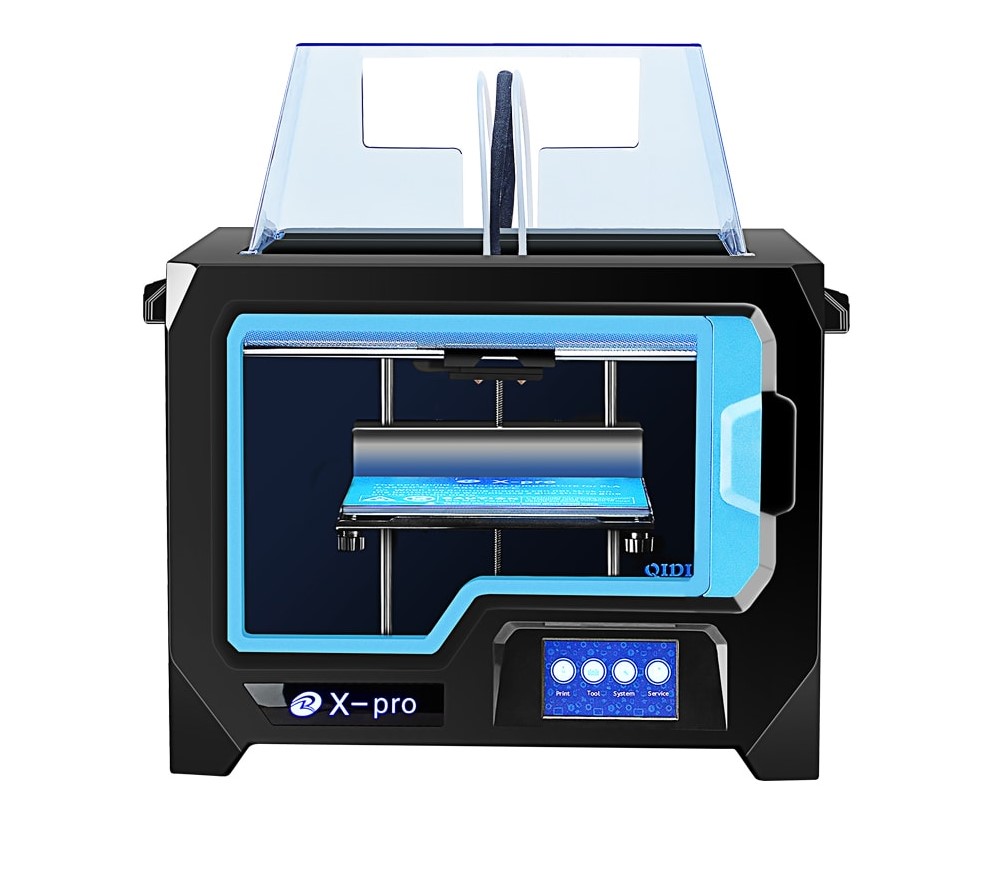

Introduction to Qidi Software for XPro

Qidi Software for XPro is revolutionizing how users interact with 3D printing technology, offering an intuitive interface that simplifies complex tasks. Its integration allows novice and seasoned professionals to seamlessly control their printers precisely, enhancing productivity and minimizing errors. The software’s robust features include customizable print settings and real-time monitoring capabilities, which empower users to optimize every project based on specific needs.

Common Issues with Qidi Software for XPro and How to Troubleshoot Them

Using the Qidi software for the XPro 3D printer has challenges. However, most common issues can be resolved with proper troubleshooting. Below are the most frequent problems users face and detailed steps to address them.

Qidi Software Not Recognizing XPro Printer

If the Qidi software fails to detect the XPro printer, it is typically due to connection issues, drivers, or outdated firmware.

Checking Printer Connections and Drivers

Ensure all cables, whether USB or Ethernet, are securely connected. If necessary, try a different port or cable. Also, check if the printer drivers are installed correctly by visiting Qidi’s website and downloading the latest version.

Updating Firmware and Software Versions

Outdated firmware or software can prevent the printer from being recognized. Make sure both the XPro firmware and Qidi software are up-to-date. After updating, restart both the computer and printer.

ALSO READ: HamGeek APX-8000 Programming Software Free Download Guide

ALSO READ: What You Need to Know About the Headstarter Software Engineering Fellow Program?

Print Jobs Not Starting or Freezing Mid-Process

Sometimes, print jobs fail to start or pause mid-way due to communication issues or G-code errors.

Resolving Communication Issues Between Software and Printer

Verify that the communication between the software and printer is stable. Try switching from USB to Ethernet for a stronger connection, or check the wireless network setup.

Checking G-code for Errors

Errors in the G-code can lead to frozen print jobs. Re-slicing the model will ensure that the slicing process is error-free and that the G-code doesn’t contain corrupt commands.

Bed Leveling and Calibration Problems

Improper bed leveling can lead to poor print quality or failed prints.

How to Manually Adjust the XPro Bed Level

Manually adjusting the bed level ensures better print quality. Use the leveling knobs beneath the bed and check for even spacing between the nozzle and the print bed at all points.

Auto-Leveling Function Issues and Fixes

If the auto-leveling function is malfunctioning, recalibrate the sensor or reset the printer’s auto-leveling settings in the software.

Poor Print Quality: Stringing, Warping, and Layer Shifts

Poor print quality can result from incorrect temperature, speed settings, or bed adhesion issues.

Adjusting Temperature and Speed Settings in Qidi Software

Optimize print temperature and speed in the Qidi software. Lowering the speed and adjusting the temperature can reduce stringing and layer shifts.

Fixing Warping with Improved Bed Adhesion and Slicing Techniques

Improving bed adhesion can minimize warping. Apply adhesive materials or use a heated bed. To enhance print stability, also adjust slicing settings, such as infill or raft thickness.

Software Crashes or Freezes

If the software frequently crashes, it may be due to memory overload or compatibility issues.

How to Prevent Memory Overload and Optimize Performance

Close unnecessary background applications and ensure the system meets the software’s requirements. Freeing up memory can improve software performance.

Reinstalling or Updating the Software for Stability

If crashes persist, reinstall the Qidi software or check for updates. This ensures that bugs or stability issues are resolved with the latest version.

Advanced Features of Qidi Software for XPro

The Qidi software for the XPro offers a range of advanced features designed to enhance the 3D printing experience. These features give users greater control over their prints, allowing customization and optimization tailored to specific needs.

Customizing Print Profiles for Specific Materials

Fine-tuning print profiles for different materials can produce better print results, especially when dealing with specialized filaments.

Creating a New Print Profile for PLA, ABS, or PETG

The software allows users to create customized profiles for various materials such as PLA, ABS, and PETG. This feature ensures the ideal temperature, speed, and layer settings are used for each filament type, enhancing the overall print quality.

Advanced Settings for Flexible and Exotic Filaments

Advanced settings can be adjusted for more challenging filaments like flexible or exotic blends. Users can modify extrusion temperatures, retraction settings, and flow rates to ensure successful prints with these materials.

Dual Extrusion Settings for Complex Prints

Dual extrusion allows for more complex prints with multiple materials or colors, adding versatility to your 3D creations.

Optimizing Dual Extrusion for Multi-Material Prints

By optimizing the dual extrusion settings, you can seamlessly print using two materials at once, such as PLA for structure and PVA for water-soluble supports. The Qidi software provides precise controls for aligning and calibrating extruders.

How to Set Up Supports and Prime Towers in Dual Extrusion Mode

Setting up supports and prime towers in dual extrusion mode ensures a smooth print process. Prime towers help maintain clean transitions between materials and well-placed supports enhance the stability of complex models.

Optimizing Print Speed and Layer Height for Precision

The balance between print speed and precision is crucial for achieving the best results, especially when working with detailed or high-resolution models.

Balancing Speed and Quality in High-Resolution Prints

You can fine-tune the print speed and layer height to achieve high-resolution prints. Slower speeds generally result in finer detail, while small layer heights contribute to smoother surfaces and higher precision.

Adjusting Layer Height for Faster Prints Without Sacrificing Quality

Adjusting the layer height can significantly reduce print time when printing larger models. Increasing the layer height slightly will speed up the print process without drastically affecting quality, making it ideal for prototypes.

Using the Temperature Control Features for Different Filaments

The software’s temperature control features allow users to preheat the bed and extruder for specific filament types, ensuring consistent performance.

Preheat Settings for Bed and Extruder

Preheating the bed and extruder to the correct temperatures for different filaments helps avoid warping or adhesion issues. The software allows users to set custom preheat profiles for various materials.

Adjusting Flow Rates for Better Filament Control

Flow rate adjustments help fine-tune how much filament is extruded during the print process. Properly controlling flow rates is essential for reducing over-extrusion or under-extrusion, especially when working with flexible or high-performance filaments.

Enabling and Optimizing Support Structures

Support structures are critical for printing complex models with overhangs or intricate designs, and the Qidi software offers options to enhance support performance.

Customizing Support Patterns for Better Detachability

Users can customize support patterns to make them easier to detach once the print is complete. Selecting the correct pattern reduces the risk of damaging the print when removing supports.

Using Tree Supports for Complex Geometries

Tree supports are ideal for models with complex geometries or delicate structures. These supports branch out to provide stability while being easy to remove post-print, preserving the fine details of the print.

Best Practices for Using Qidi Software for XPro

Using the Qidi software for the XPro effectively requires following best practices to ensure smooth operation and optimal print quality. By adhering to these tips, you can maximize the performance of both the software and the printer.

Keeping Your Software and Firmware Updated

Regularly updating the Qidi software and firmware of your XPro printer is essential for ensuring compatibility with new features and bug fixes. Updates often bring enhancements that improve print quality, reliability, and user experience. It’s recommended that you check for updates frequently through the software interface.

Regular Maintenance of Your XPro Printer for Better Performance

Consistent printer maintenance is critical to extending the lifespan of your XPro and ensuring consistently high-quality prints. Cleaning the print bed and extruders and checking for worn-out components like belts or pulleys will help maintain precision. Running routine maintenance through the software can also assist in keeping your printer running smoothly.

Saving and Sharing Custom Profiles with the Qidi Community

One of the strengths of the Qidi software is the ability to create and save custom print profiles. Users should make and fine-tune profiles tailored to their specific materials and print needs for the best results. Additionally, sharing these profiles with the Qidi community fosters collaboration and helps other users benefit from your optimized settings.

ALSO READ: How to Use Tuning Software for Stagg 21 Kalimba on a Mac?

ALSO READ: How do you install and use Isuzi OBDLink EX software for vehicle maintenance?

Frequently Asked Questions (FAQs)

Can I Use Third-Party Software with My Qidi XPro?

You can use third-party slicers like Cura or Simplify3D with the Qidi XPro by importing the correct printer settings.

How Do I Resolve Print Bed Adhesion Problems?

Ensure the bed is clean and adequately leveled, use a suitable adhesive like glue or tape, and adjust the bed temperature to improve adhesion.

What Are the Best Settings for Dual Extrusion Prints?

For dual extrusion prints, use prime towers, adjust retraction settings to avoid oozing, and set optimal print temperatures for both materials.

Why Is My Printer Pausing During Long Prints?

Printer pauses during long prints may be due to a lack of filament, power interruptions, or communication issues between the printer and software.

How Do I Customize Material Profiles in Qidi Software?

In the Qidi software, go to the print settings, select or create a new profile, and adjust parameters like temperature, speed, and extrusion rates for the specific material.

Conclusion

In conclusion, Qidi Software for XPro offers many features to enhance your 3D printing experience, from troubleshooting common issues to unlocking advanced functionalities. By familiarizing yourself with these tools, you can significantly improve print quality and streamline your workflow.

Whether you’re a beginner or an experienced user, understanding the software’s capabilities will empower you to achieve optimal results. Remember that exploring these advanced features can take time, but the rewards are worth the effort. Dive into Qidi Software today and transform your 3D printing projects!